Lock in Freshness

Instantly

Cool your milk from 35°C to 4°C in under 2.5 hours.

Available from 1,000L to 30,000L. Designed for maximum hygiene, energy efficiency, and preserving Class A milk quality.

Built for Premium Milk Quality

Rapid Cooling Speed

High-performance evaporators cover large surface areas, ensuring milk drops to 4°C quickly to inhibit bacterial growth (ISO 5708 Standard).

Thermal Insulation

60-80mm high-density polyurethane foam. Keeps milk cold for 24 hours even if the power goes out (Temp rise < 2°C).

Auto-Wash System

Integrated CIP (Clean-in-Place) system with rotating spray balls ensures 360° coverage. No dead corners for milk residue.

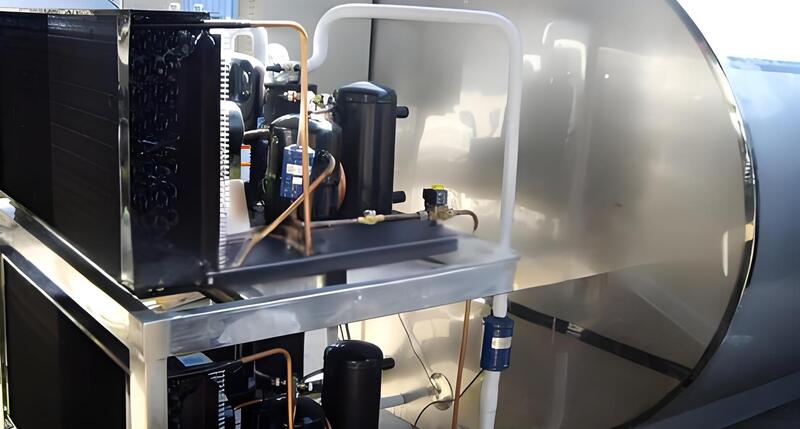

Famous Compressors

Equipped with Copeland (USA) or Maneurop (France) scroll compressors. Reliable, quiet, and easy to service globally.

Sanitary Construction

Proven Performance

See how our tanks perform in extreme conditions.

Common Questions from Dairy Farmers

Expert answers to help you choose the right tank.

01

How do I choose the right capacity for my herd?

We recommend a tank that holds 2-3 days of milk production. This allows for everyday pickup or every-other-day pickup with a safety buffer. For example, if you produce 2,000L per day and truck collects every 2 days, a 5,000L or 6,000L tank is ideal.

02

What power supply is required?

For tanks 1 Ton and larger, a 3-Phase power supply (380V/415V, 50Hz/60Hz) is standard to run the heavy-duty compressors and agitators efficiently. Single-phase is only available for small tanks under 1,000L.

03

Can I install the cooling unit outside?

Yes, and we recommend it for tanks larger than 5 Tons. Our Split Type models allow the condensing unit to be placed outdoors with a roof cover. This keeps the heat generated by the compressor out of your milk room, improving efficiency and hygiene.

04

Does the tank clean itself?

Yes. All our Horizontal tanks come with an Automatic CIP (Clean-In-Place) System. You simply hook up hot water and cleaning chemicals, press a button, and the system runs a timed cycle of Rinsing, Washing, and Final Rinsing using high-pressure rotating spray balls.

Stop Milk Spoilage.

Upgrade Your Tank.

From 1 Ton to 30 Tons, we have the right cooling solution. Get a custom quote including shipping to your location within 24 hours.