Maximum Speed &

Throughput

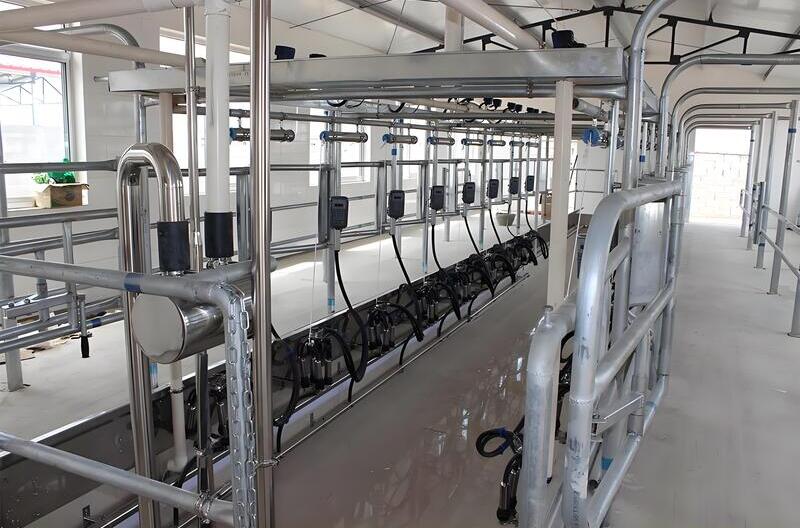

The ultimate solution for commercial herds (500-1,000 cows). Featuring 90-degree positioning and Rapid Exit technology to reduce milking time by up to 30% compared to traditional systems.

Why Upgrade to a Parallel System?

Rapid Exit Framework

- Lift System: Heavy-duty pneumatic cylinders for fast gate lifting.

- Cabinet: AISI 304 Stainless Steel upper cabinet for electronics protection.

- Spacing: Standard 28" (71cm) cow spacing for compact efficiency.

- Splash Guard: Integrated stainless steel manure gutter and butt pan.

Global Success Stories

Commercial dairies trusting our Parallel systems.

We Support You Beyond Installation

Lifetime support directly from the factory experts.

2-Year Critical Spares Kit

We include a free kit of essential spares (liners, seals, gaskets) with every order.

Remote Engineer Access

Direct WhatsApp/Video access to our engineers for troubleshooting (No call centers).

Global Logistics

We handle container loading and customs documentation for over 50 countries.

Ready to Upgrade Your

Milking Efficiency?

Send us your barn dimensions or project requirements. Our engineers will provide a free 3D layout design and a detailed quotation within 24 hours.

Request Received!

Our engineering team is analyzing your herd requirements. We will send the 3D layout proposal to your email shortly.