The Power of

Continuous Flow

The ultimate high-throughput solution for herds over 1,000 cows. Designed for 24/7 heavy-duty operation, maximum labor efficiency, and seamless automation integration.

Why Choose Our Rotary System?

Heavy-Duty Platform Design

- Deck Material: Concrete with rubber mats or Non-slip Steel deck.

- Rollers: Industrial Nylon rollers (self-lubricating) for smooth rotation.

- Track: Precision-engineered "I-Beam" steel track.

- Sizes: Available from 24 to 80+ milking points.

Success Story

Proven performance in large-scale Chinese dairies.

60-Point Internal Rotary

- • Internal Herringbone Design for Maximum Visibility

- • 3,500 Cows Milked 3x Daily

- • Heavy-duty Nylon Roller System (Non-stop Operation)

"The internal design gives our milkers a perfect view of every udder, ensuring hygiene standards. Combined with the heavy-duty roller system, it handles our 22-hour daily operation with ease."

We Support You Beyond Installation

Lifetime support directly from the factory experts.

2-Year Critical Spares Kit

We include a free kit of essential spares (liners, seals, rollers) with every order.

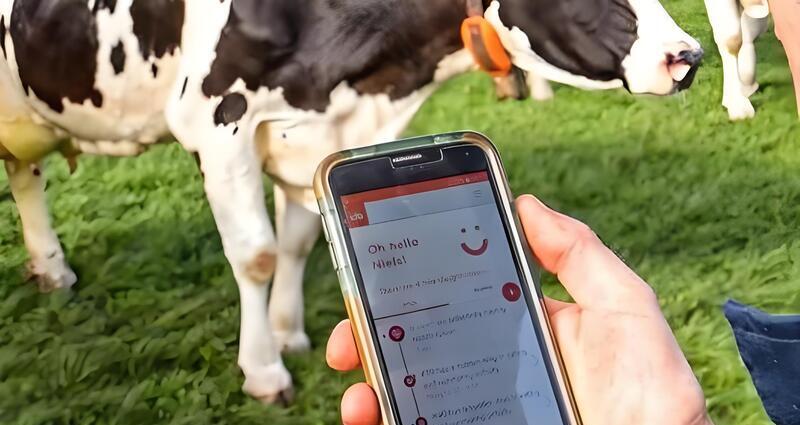

Remote Engineer Access

Direct WhatsApp/Video access to our engineers for troubleshooting (No call centers).

Global Logistics

We handle container loading and customs documentation for over 50 countries.

Planning a Mega Dairy?

Let's Talk Scale.

Designing a rotary parlor requires precision engineering. Send us your project requirements, and our engineers will provide a custom 3D proposal and ROI analysis within 24 hours.

Request Received!

Our engineering team is analyzing your herd requirements. We will send the 3D layout proposal to your email shortly.