Artisan Craft Meets

Industrial Precision

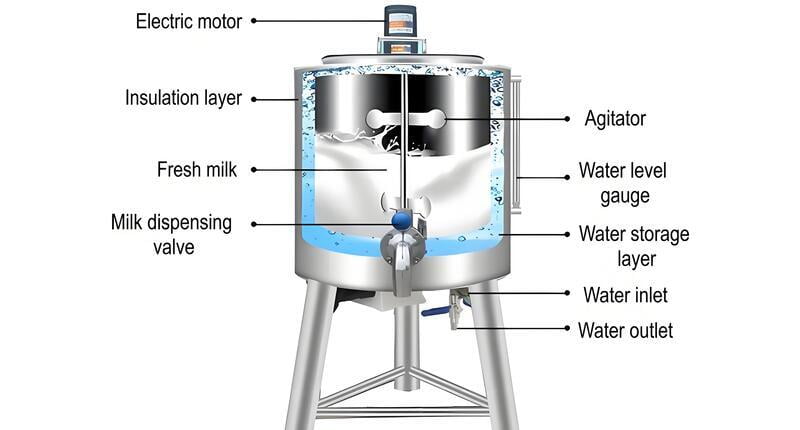

The ultimate all-in-one thermal processing vat. Pasteurize milk, incubate yogurt, or mix cheese curds in a single unit. Gentle water-bath heating preserves the natural flavor of your dairy products.

Why Choose Our Batch Pasteurizers?

Sanitary Vessel Design

- Material: 100% High-grade SUS304 Stainless Steel (inner and outer).

- Insulation: Injected polyurethane foam layer for maximum heat retention and energy saving.

- Interior Finish: Mirror-polished inside out. Seamless arc transitions (Ra≤0.4um) prevent bacteria buildup.

Common Questions from Food Makers

Click on a question to view the answer.

01

Can I use this machine to make yogurt or cheese?

Yes, absolutely. This is the primary advantage of a Batch Type vat. You can heat the milk to pasteurization temperature, run cold water through the jacket to drop the temperature to 42°C, add your bacterial cultures, and use the digital thermostat to hold that exact temperature for yogurt fermentation or cheese renneting.

02

Do I need an external steam boiler to heat the vat?

No, it is self-contained. Our standard commercial batch pasteurizers (30L-150L) use built-in electric heating elements located in the bottom water jacket. You simply plug the machine into an electrical outlet and fill the jacket with water.

03

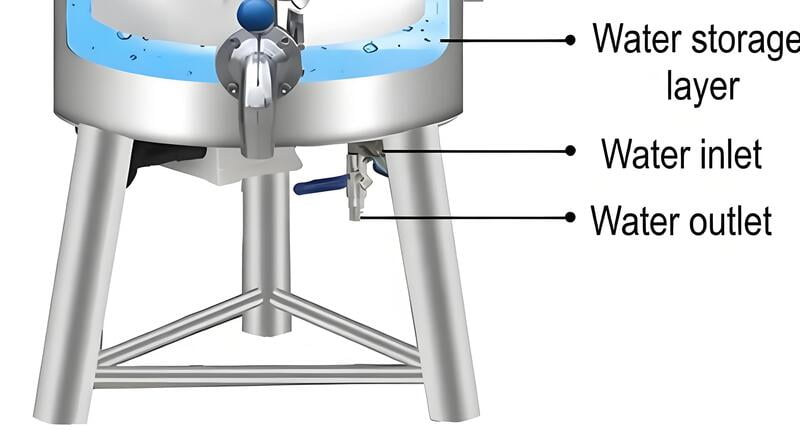

How does the cooling process work?

After the heating cycle finishes, you connect standard tap water (or chilled water from an ice bank) to the inlet valve. The cold water flushes through the jacket, pushing out the hot water, rapidly bringing down the temperature of the milk inside while the agitator keeps it circulating.

04

Does it require 3-Phase power (380V)?

The smaller 30L to 150L units can be custom-wired for either Single-Phase (220V) or 3-Phase (380V) power, making them perfectly suitable for small retail shops or farms without industrial power. Larger industrial vats (500L+) require 380V due to the higher heating loads.

Need the Perfect

Capacity for Your Recipe?

Tell us what product you are making (milk, yogurt, cheese) and your daily volume. Our engineers will recommend the exact vat size and heating configuration you need within 24 hours.