Complete

Processing & Packaging

End-to-end solutions for dairy perfection. From turnkey automated production lines to high-precision filling, we protect your product's quality, stability, and your bottom line.

Which processing stage do you need to optimize?

Dairy Production Line

Turnkey solutions offering seamless operation. Built-in thermal recovery systems drastically cut daily utility expenses.

Explore LinesProcessing Equipment

High-performance homogenizers to eliminate fat separation and rapid cooling tanks to instantly halt bacterial growth.

Explore EquipmentPackaging Equipment

Intelligent filling lines for cups and bottles. Flawless dosing accuracy combined with secure, retail-ready sealing.

Explore Systems

Dairy Production Lines

"Solve High Labor Costs" — Fully automated processing from raw milk to final product.

- ▪ Effortless Automation: Why patch together mismatched equipment? Our continuous production lines handle preheating, homogenization, sterilization, and cooling seamlessly. This eliminates the need for constant manual oversight, allowing you to reallocate labor and reduce payroll costs.

- ▪ Radical Energy Savings: Designed with intelligent thermal exchange layouts, the system recaptures massive amounts of thermal energy during the heating and cooling cycles, drastically lowering your facility's monthly utility bills.

Processing Equipment

"Stop Separation & Spoilage" — Industrial homogenizers and rapid chillers.

- ▪ Eliminate Whey Separation: Consumers reject uneven textures. Our high-pressure homogenizing units force liquids through microscopic valves, permanently suspending fat particles. The result is a richer, creamier mouthfeel that stays perfectly stable on the shelf.

- ▪ Instant Bacteria Suppression: Protect your batch integrity. Our chilling tanks utilize highly efficient thermal jackets and robust enclosed compressors to bring milk down to safe storage temperatures rapidly, preserving its Grade-A freshness.

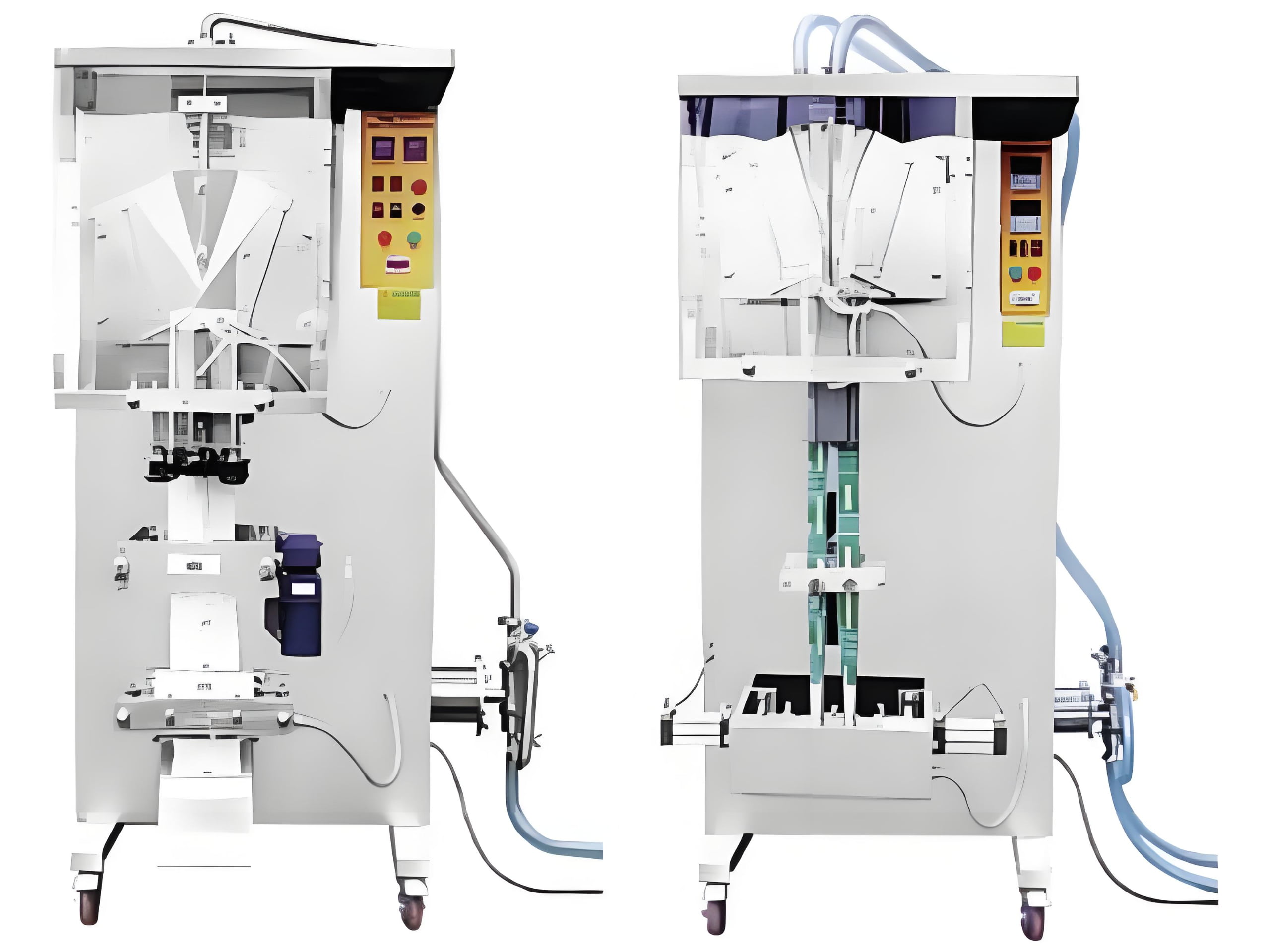

Packaging Equipment

"Stop Product Giveaways" — Precision filling and leak-proof sealing.

- ▪ Protect Your Margins: Inaccurate machinery gives away free product with every cycle. Our advanced dosing heads provide strict volume control, minimizing errors so you can maximize the profitability of every batch.

- ▪ Extend Shelf Appeal: A leaky package damages your brand reputation. Managed via an intuitive touchscreen interface, our equipment applies consistent heat and pressure to deliver a tight, flawless seal that extends product longevity and looks fantastic on retail shelves.

Standard on Every System

NexAgri Engineering Standards

CIP / SIP Ready

Say goodbye to manual scrubbing. Our internal fluid dynamics are optimized for automated cleaning-in-place, forcefully circulating sanitizers to eliminate residues without costly equipment teardowns.

Uncompromising Hygiene

Built from heavy-duty sanitary stainless steel. Every interior surface undergoes ultra-fine polishing with smooth arc transitions, guaranteeing zero dead zones where bacteria could hide.

Intelligent PLC Control

Powered by top-tier international electrical components, the digital interface lets you store product recipes and track performance in real-time, removing human error from the equation.

Ready to upgrade your production capacity?

Let us know your daily target and container type. We'll engineer the perfect setup for your facility.